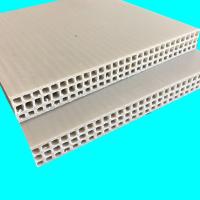

15mm 2440x1220mm pp plastic hollow formwork building concrete mold

construction material

1220x2440*12mm build pp hollow plastic formwork

Products Advantage:

1. Light weight, high strength, high hardness, impact resistance, wear

resistance.

2. Surface is smooth, bright and clean; Concreting and forming effect is good for perforated steel plank.

3. No absorption of moisture, no deformation, no mildew; Long-term immersion stratification in the water, no bubbles, sheet size stability, especially suitable for underground and damp

environment.

4. Good toughness. perforated plank concrete wall panel system could be used as cambered special-shaped formwork.

5. Acid and alkali resistance, corrosion resistance; perforated plank concrete wall panel system is very suitable for the engineering application in coastal areas, mine, as well as seawall. perforated steel plank needs not do any preservative treatment both in using and storing

the formwork, which do not pollute the concrete surface.

6. The reusable time for perforated steel plank can reach more than 60 times, long service life.

7. Waste products can be recycled and reprocessed, making full use

of waste materials. This property can greatly reduce the project cost compared with wooden formwork and bamboo formwork.

8. Environmental protection and energy saving, no pollution. No any poisonous or harmful gas.

9. Demould easily. No need brushing release agent, only tapping,

the perforated plank concrete wall panel system will fall off. Shorten working hours and speed up the construction schedule efficiently.

10. Easy to process. Sawing, drilling and nailing are all

available. perforated plank concrete wall panel system can be combined vertically and horizontally optionally.

11. Easy to remove. Removing is convenient, quick and safe, and the

supporting is also easy to operate, advantageous to the organization construction, effectively improving the

construction schedule.

General Operation And Notes Of Instrument

For perforated plank concrete wall panel system :

- Method of use as well as wooden formwork, perforated steel plank

reinforcement direction with batten direction placed in cross

shaped.

- No need to smear the mold release agent before using perforated

plank concrete wall panel system

- When cast-in-place the flat plate, spacing between the keels should

be 20 ~ 25 cm, and the spacing between the wall plate and keels

hould be 10 ~ 20 cm. perforated plank concrete wall panel system

don't need releasing agent.

- The seam-line between perforated steel plank should be taped.

- The length of nail should not be too long, generally about 30 ~ 35

mm.

- The strength to drive nails should be moderate.

- When removing the perforated plank concrete wall panel system,

please start from the small part of one end, the support and the

plates should be removed at the same time aiming at preventing the

template widespread drops, don't let the corner drop on the ground

vertically.

- The perforated plank concrete wall panel system accesses to be

mixed used with wood veneer, bamboo veneer and other material

plate.